|

|

Annular BOP

The design and manufacture of Annular BOP is according to API Spec 16A standard.

Annular BOP also provide positive pressure control for stripping drill pipe into and out of the hole, They are available in bolted cover, wedge cover models.

There are also special lightweight models for airlifting and Arctic models for low temp. service.

SPECIAL FEATURES:

●Packing element is spherical or tapered type with massive storage volume, low operation pressure and excellent sealing function.

●Piston is set in low position to have a shorter moving distance; Use wear ring on piston.

●Bonnet is hemispherical-shaped, so there is no stress concentration on bonnet whenever bearing the pressure. so the pressure is evenly distributed; convenient for disassembly and assembly.

●Lip type seal rings are used to realize long service life.

●Simple hydraulic system, Only two hydraulic Connections are needed.

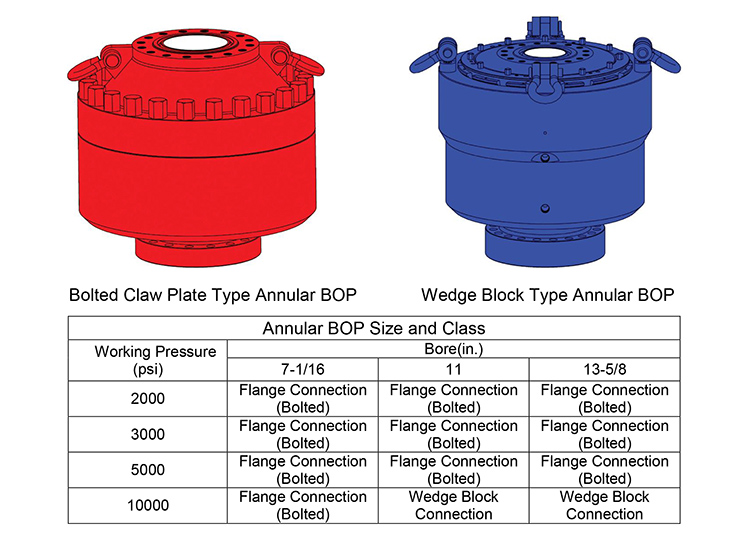

Bolted Claw Plate Type Annular BOP

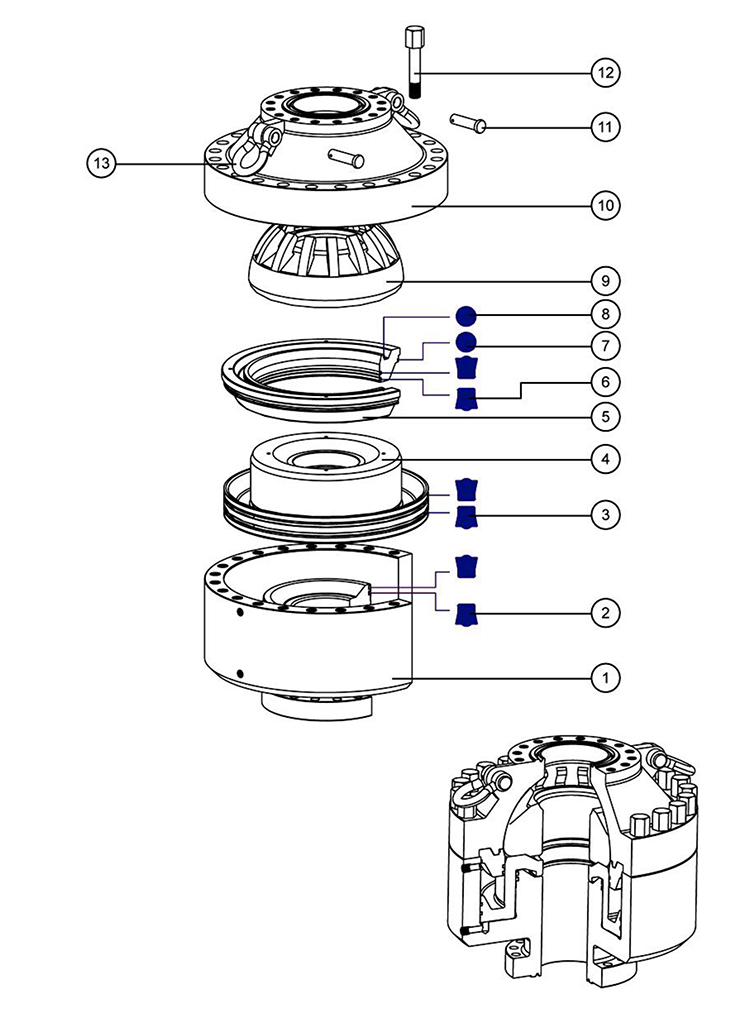

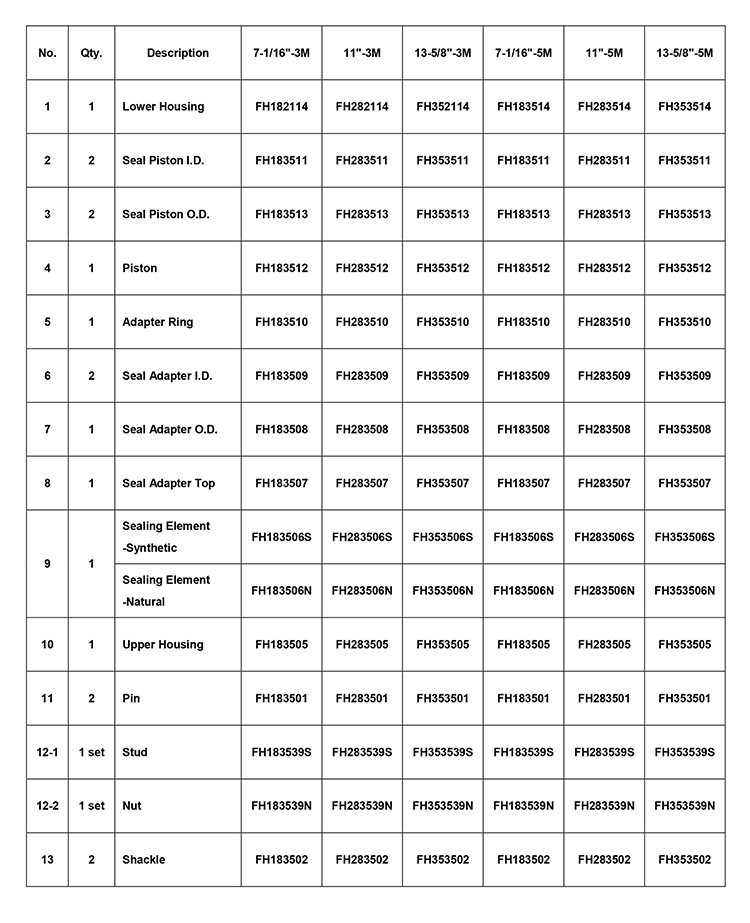

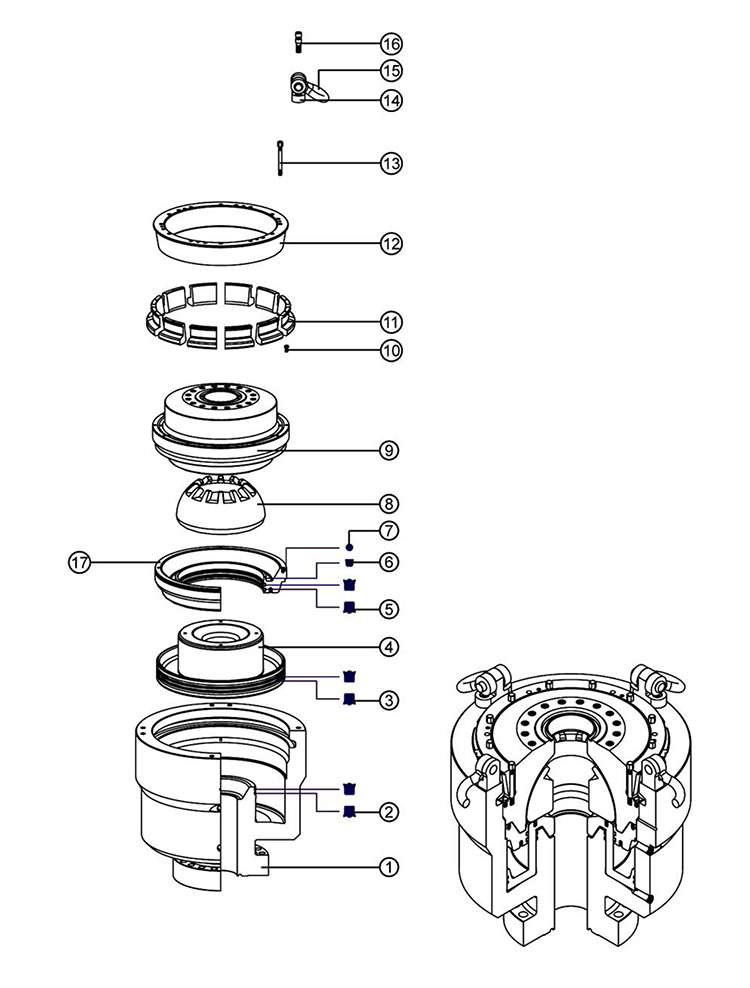

Bolted Claw Plate Type Annular BOP Part Numbers

Wedge Block Type Annular BOP

Wedge Block Type Annular BOP Part Numbers

ANNULAR BOP INSTALLATION AND OPERATION

INSTALLATION RECOMMENDATIONS

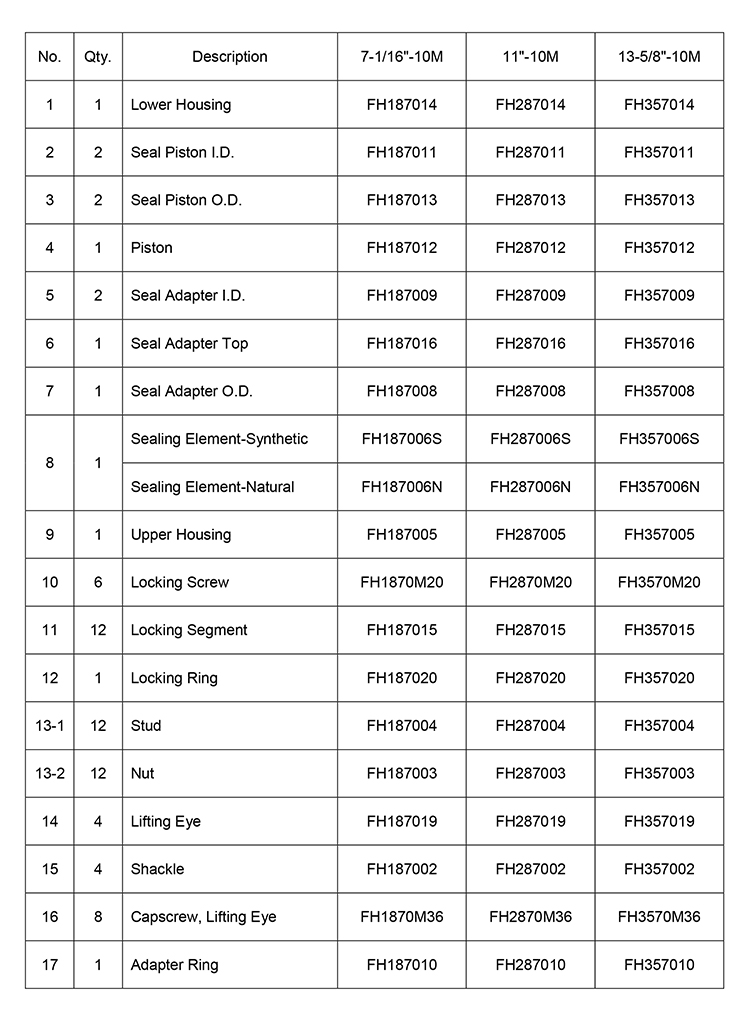

A blowout preventer operating and control system Is required to activate the Annular BOP. Several systems are available. Those normally used on Drilling rigs work well. The recommended installation requires:

1. A control line to the closing (lower) port.

2. For stripping, an accumulator bottle in the closing line adjacent to the BOP. This bottle should be pre-charged to 500psi for surface installations and to 500psi plus 45psi per 100’ of water depth for sub-sea installations.

3. A control line to the opening (upper) port.

4. A hydraulic regulator to allow adjustment of operating pressure to meet any given situation. The hydraulic operating fluid should be hydraulic control fluid with a viscosity between 200 and 300 SSU at 100F. NL-100 hydraulic control fluid is recommended. It is water-soluble and environmentally acceptable. For freeze protection, ethylene glycol replaces some of the water in the mix.

NOTE: Some water-soluble systems will corrode the metals used in BOPs. If water-soluble oil other than NL hydraulic control fluid is used, be sure that it provides adequate lubrication and corrosion protection.

OPERATING REQUIREMENTS

1.Annular have relatively simple operating requirements compared to other annular Bops. When closing on stationary pipe, a maximum of 1500psi operation pressure is sufficient. Recommended closing pressures for specific applications are given in the table on this page.

1.Annular have relatively simple operating requirements compared to other annular Bops. When closing on stationary pipe, a maximum of 1500psi operation pressure is sufficient. Recommended closing pressures for specific applications are given in the table on this page.

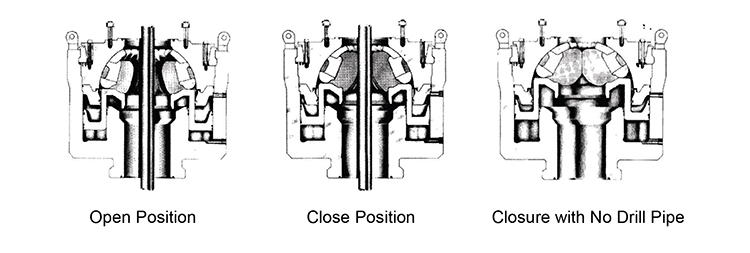

2.The illustrations on the next page show the closing action of Annular BOPs in sealing around drill string or across the bore when no drill string is present.

3.Closing action begins when hydraulic fluid is pumped into The closing chamber of the Annular BOP below the piston. as the piston rises, it pushes the element up, and the element’s Annular shape causes it to close in at the top as it moves upward.

4.The element seals around the drill string as the piston continues To rise. Steel segments in the element move into the well bore to Support the rubber as it contains the well pressure below.

5.When there is no pipe in the preventer, continued upward movement of the piston forces the element to seal across the open bore. At complete shutoff, the steel segments provide ample support for the top portion of the rubber. This prevents the rubber from flowing or extruding excessively when confining high well pressure.

ANNULAR BOP OPERATION

STRIPPING OPERATIONS

Stripping operations are undoubtedly the most severe application for any preventer because of the wear the sealing element is exposed to as the drill string is moved through the preventer under pressure. To prolong sealing element life, it is important to use proper operating procedures when stripping. The recommended procedures are:

1. Close the preventer with a maximum of 1500psi closing pressure.

2. Just prior to commencing stripping operations, reduce closing pressure to a value sufficient to allow a slight leak.

3. If conditions allow, stripping should be done with A slight leak to provide lubrication and prevent excessive temperature buildup in the element. As the sealing element wears, the closing pressure will need to be incrementally increased to prevent excessive leakage.

4. If conditions will not allow leakage during stripping operations, the closing pressure should be adjusted to a value just sufficient to maintain a seal.

5. As required closing pressure approach 1500psi, Consideration should be given to switching to another preventer to complete stripping operations. The minimum pressure required to maintain a seal during stripping will vary, depending on the particular element and its service history.

ORDERING A SPHERICAL BOP

When ordering a Annular BOP, specify the following:

1. Bore size and working pressure

2. Connections:

Bottom connection. Studded, flanged required. Give size, working pressure and ring groove. Unless specified otherwise, API ring groove will be supplied.

3. Top connection. Studded, flanged required. Give size, working pressure and ring groove. Unless specified otherwise, API ring groove will be supplied.

4. Element –Synthetic or natural rubber.

5. Spare parts. Recommended spare parts are the quantities shown in the parts lists of this catalog. Seal kits include all the recommended spare seals.