|

|

Wellhead and Christmas Tree

Wellhead and Christmas Tree

Wellhead and Christmas Tree

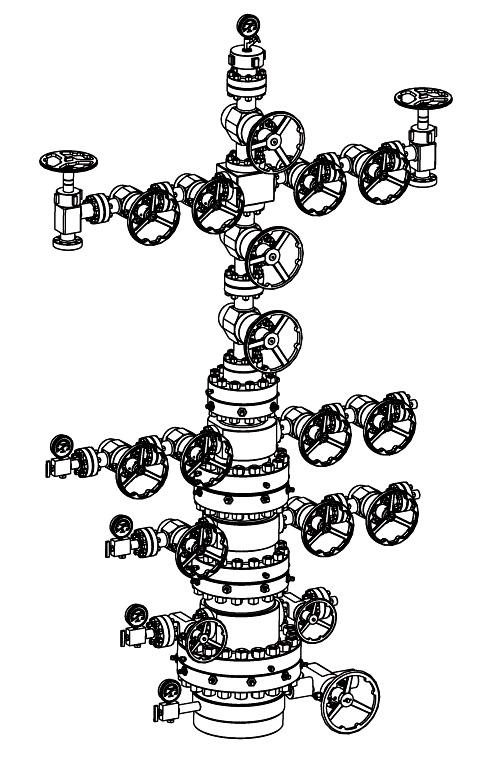

Our company supplies wellhead and Christmas trees suitable for inland and offshore applications to explore, develop and produce oil. Design, produce, manufacture, test and quality control are all according to API 6A, latest edition. The main pressure parts of these products are made of forgings or specially smelted low alloy steel (stainless steel), having high bearing strength. Wellheads manufactured by our company are available in 10,000psi maximum working pressure and 500 tons maximum suspending capacity, material classes from AA through FF, temperature classes from L through V, product specification levels from 1 through 4 and PR1-2, and are accordance with NACE Standard MR0175.

We have many different kinds of configurations, meeting requirements of all kinds of bore frames and casing programs, providing service in different working conditions. Christmas trees and auxiliary equipments are available at your option. Wellheads also can be designed and manufactured to customers requirements.

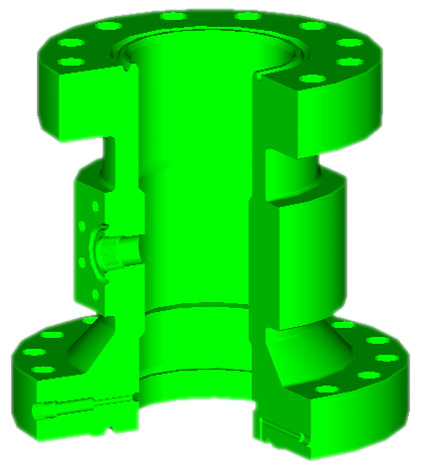

Casing Head Assembly

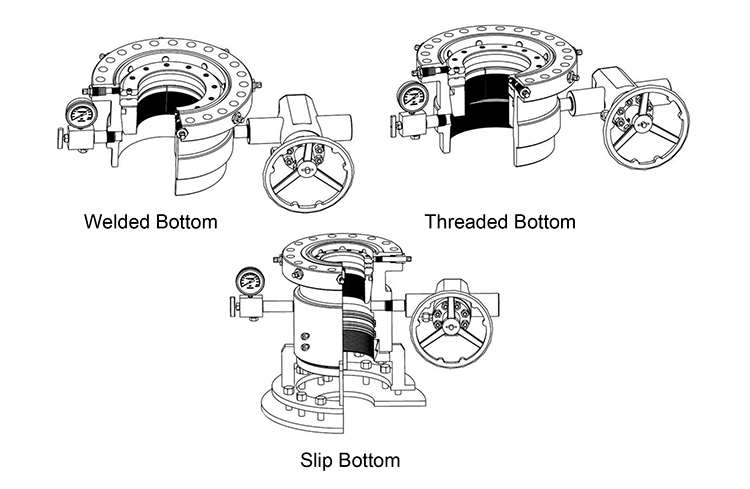

The casing head assy. is a kind of part of connecting casings and wellheads. It is used as supporting the weight of technical casing and oil string casing ,sealing the annular space between the casings, It provides a transition joint for the tubing head, Christmas tree and other wellheads, It can also supply cement, monitor and control well’s sinking, inject balance liquids etc through the two side outlet on the casing head housing.

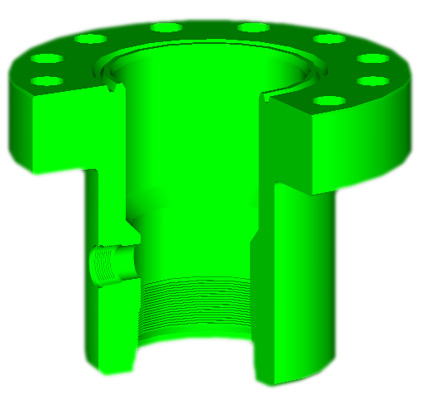

The casing head produced by our company is a standard structure, in which the casing hanger produced by our company is fitted, The casing hanger can be elected on size according to the casing procedure and the change of well head condition. On the upper of the casing heads sets all API 6B or API 6BX flange.

The bottom connection of the casing head shall be either API perfect circle thread casing box or API standard form casing threaded box, socket welded connection and slip type connection as well.

It can be provided with weld-group supporting baseplate.Side outlets are provided with pipeline threaded connection and bolted connection, bolted side outlet is machined with female thread of VR valve-changer.

C-22 Casing Heads

C-22 casing heads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Straight Bore Design:

Features a 45°landing shoulder capable of supporting maximum loads.

Features a 45°landing shoulder capable of supporting maximum loads.

Prevents test plugs from wedging under pressure.

Manufacturing Standard:

API Spec 6A, PSL2, DD,P U,PR1.

Outlets:

Line Pipe Outlets;

Studded Side Outlets;

Extended Flanged Outlets.

Casing Hanger Compatibility:

Slip-type casing hangers;

Mandrel style casing hangers.

Bottom Connections:

Slip-on weld;

Slip-on weld with O-ring;

Threaded.

Lock-screws:

Casing heads are supplied with 2 lock-screws for wear bushing retention;

Casing heads are supplied with 2 full set of lock-screws for mandrel casing hanger and pack off retention.

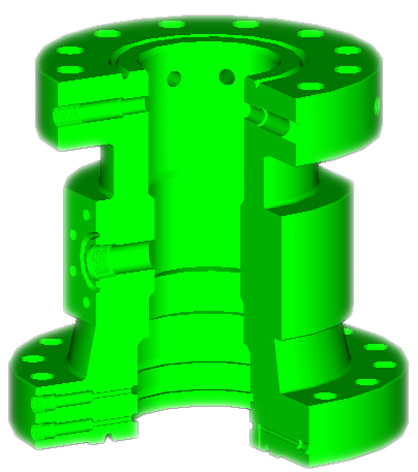

C-22 Casing Spools

C-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Straight Bore Design:

Features a 45°landing shoulder capable of supporting maximum loads.

Features a 45°landing shoulder capable of supporting maximum loads.

Prevents test plugs from wedging under pressure.

Manufacturing Standard:

API Spec6A, PSL2, DD,P U,PR1.

Outlets:

Line Pipe Outlets;

Studded Side Outlets;

Extended Flanged Outlets.

Casing Hanger Compatibility:

Slip-type casing hangers;

Mandrel style casing hangers.

Bottom Connections:

For use with PE secondary seal bushing;

For use with HPE secondary seal bushing for high pressure applications.

Lock-screws:

Casing heads are supplied with 2 lock-screws for wear bushing retention;

Casing heads are supplied with 2 full set of lock-screws for mandrel casing hanger and pack off retention.

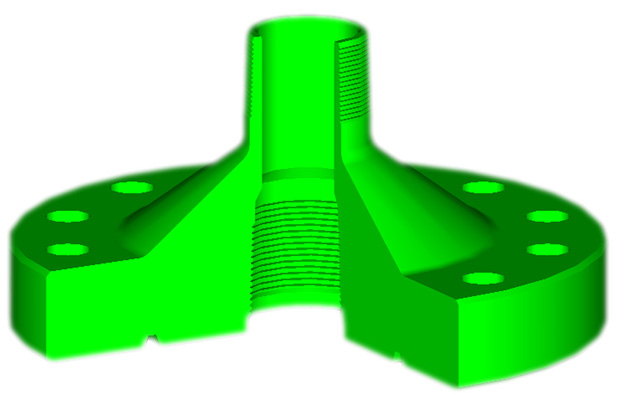

TCM Tubing Head Spools

TCM tubing head spools feature a versatile straight bore design for single and multiple completions. This design accepts all tubing hangers and easily converts from a single completion to multiple completion with the addition and alignment pins.

Straight Bore Design:

Straight Bore Design:

Features a 45°landing shoulder capable of supporting maximum loads.

Manufacturing Standard:

API Spec6A, PSL2, DD,P U,PR1.

Outlets:

Line Pipe Outlets;

Studded Side Outlets.

Tubing Hanger Compatibility:

Tubing heads accept a wide variety of tubing hanger styles including mandrel and wrap-around.

Bottom Connections:

For use with PE secondary seal bushing;

For use with HPE secondary seal bushing for high pressure applications.

For use with HPE secondary seal bushing for high pressure applications.

Lock-screws:

Tubing heads are supplied with EFT style lock-screws.

Available Sizes:

Available with 7-1/16”nominal bowl compatible with 7-5/8”production casing,9”nominal bowl compatible with 8-5/8”production casing and11”nominal bowl compatible with 9–5/8”production casing.