|

|

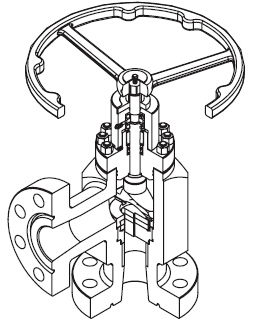

Gate Valve and Choke Valve

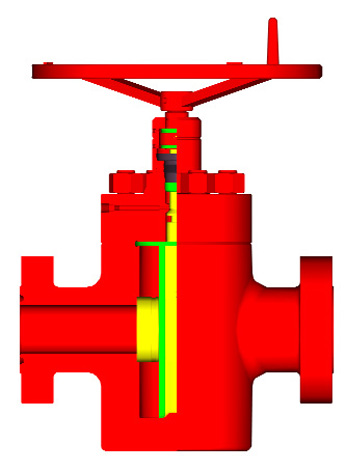

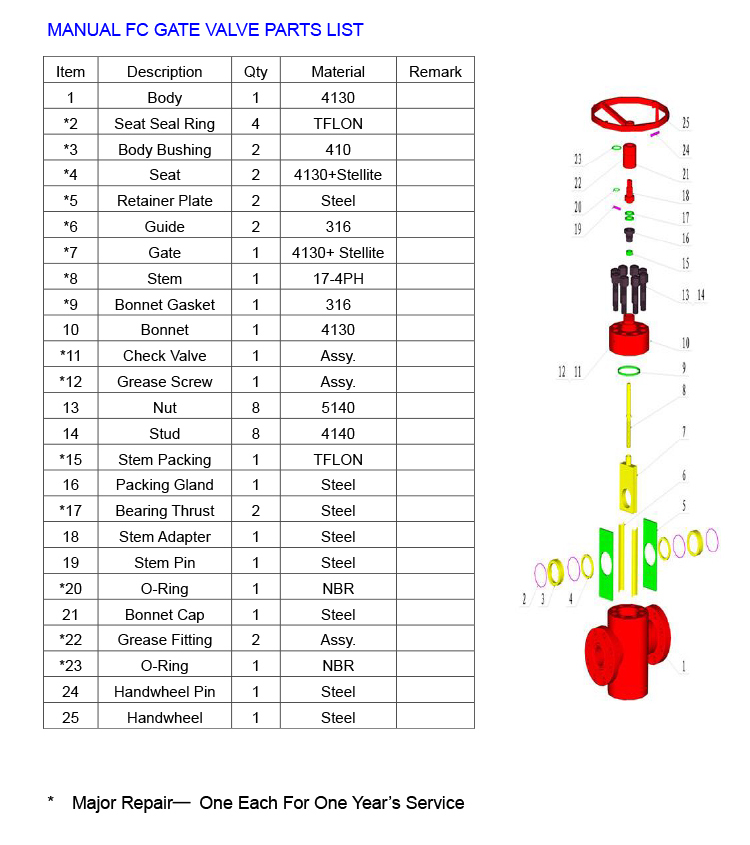

(Interchangeable with Cameron® Model FC Gate Valve)

The FC gate valve features a non-rising stem with a slab gate, Full-Bore Thru-Conduit Design, Floating Slab Gate and Seats , floating seat ring body bushing design to provide safe dependable service. It is available in flanged or threaded ends in standard bore sizes from 1-13/16”thru 7-1/16”in working pressures of 5,000 psi thru 10,000 psi wp. Seat rings, body bushings, gate, stem are easily replaced in the field, Simple routine maintenance program limits repairs, eases operation, protects against corrosion, and extends service life.

The FC gate valve features a non-rising stem with a slab gate, Full-Bore Thru-Conduit Design, Floating Slab Gate and Seats , floating seat ring body bushing design to provide safe dependable service. It is available in flanged or threaded ends in standard bore sizes from 1-13/16”thru 7-1/16”in working pressures of 5,000 psi thru 10,000 psi wp. Seat rings, body bushings, gate, stem are easily replaced in the field, Simple routine maintenance program limits repairs, eases operation, protects against corrosion, and extends service life.

SPECIFICATION

● Manufactured and Tested in Accordance with API Spec6A

● Forged Steel Body and Bonnet

● A True Bi-Directional Valve

● Low Operating Torque

● Quick Release Hand Wheel

● API Spec6APSL, 1, 2, 3

● Material Classes DD, EE, FF, to NACE MR-01-75

● Available from 5000 psi to 10,000 psi in all Full-Bore Sizes

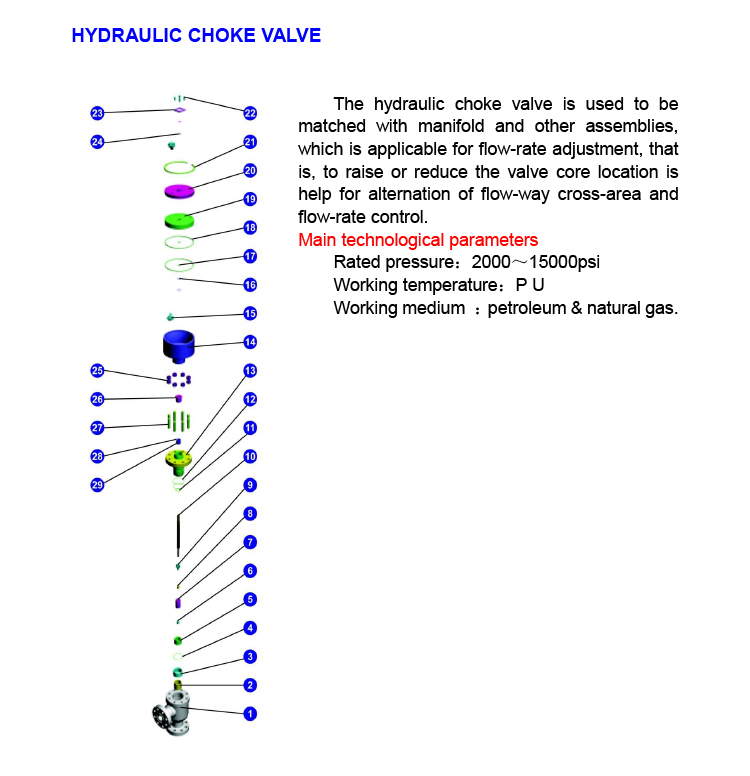

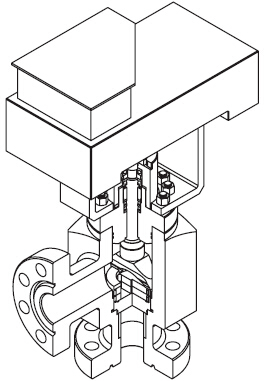

Super Choke Valve (Manual & Hydraulic Actuator)

The super choke valves are the most widely used and respected well-killing and high-pressure-control drilling chokes in the industry. For more than 35 years, these chokes have been especially effective when used during well kicks, well testing and well cleanup operations. They are designed and manufactured for H2S and abrasive-fluid applications and in accordance with API and NACE standards.

The super choke valves are the most widely used and respected well-killing and high-pressure-control drilling chokes in the industry. For more than 35 years, these chokes have been especially effective when used during well kicks, well testing and well cleanup operations. They are designed and manufactured for H2S and abrasive-fluid applications and in accordance with API and NACE standards.

The super manual & hydraulic actuator choke valve is molded of two pieces of special carbon tungsten plates with rather ability of erosion resistance, one of which rotates to alter the concentricity between the upper orifice and lower orifice of two plates so as to adjust the flow-rate of fluid or gas.

The valve is used for manifold such as drilling, fracture, mud circuit, ground high-pressure gas injection/production, it has a outstanding feature that the pressure difference between inlet and outlet, as closing, can press both of the plates fast together so as to put into effect of sealing cutting, especially in the case that the pressure suddenly rises or falls, the pre-set sign-rate of high/low pressure sensor can be helpful for automatic closing/shut so as to avoid heavy accident. It is outstanding advantage that it has long working life and ability of erosion/corrosion resistance in comparing with other choke valves.

The valve is used for manifold such as drilling, fracture, mud circuit, ground high-pressure gas injection/production, it has a outstanding feature that the pressure difference between inlet and outlet, as closing, can press both of the plates fast together so as to put into effect of sealing cutting, especially in the case that the pressure suddenly rises or falls, the pre-set sign-rate of high/low pressure sensor can be helpful for automatic closing/shut so as to avoid heavy accident. It is outstanding advantage that it has long working life and ability of erosion/corrosion resistance in comparing with other choke valves.

Functional Specification

High-pressure drilling chokes. Built to handle class 900# to 1,500# (2,025 psi to 3,375 psi) ,Super choke valves are precision engineered for precise well control.

Unique choke-plate design

Heavy-duty, diamond-lapped tungsten-carbide plates are honed to a flatness measured by light bands and feature unique half-moon-shaped orifices. Rotation of the actuator fork allows finite regulation of the size of the opening from full open to full close.

Positive closure

A 17° deadband overlap beyond the full-close position is designed to ensure closure even if the plates become worn following extended exposure to abrasive-laden fluid flow.

Pressure drops or surges don’t affect the quality of the seal in the plate-to-plate design. In fact, the seal improves under pressure.

Tungsten-carbide wear sleeves

Hardfacing on wear sleeves increases in-service life. Extended wear sleeves are available to absorb effects of abrasive downstream turbulence, especially during underbalanced drilling operations.

Versatile

Ideal for onshore and offshore applications. Controls can be operated from either remote or onsite consoles.

Features

Built for the oilfield

Precision engineered

Handles class 900# to 1,500 #

Unique choke-plate design

Provides positive closure

Tungsten-carbide wear sleeves extend in-service life

Versatile for onshore and offshore applications

Benefits

Delivers precise well control

Seal actually improves under pressure

Controls can be operated from either remote or onsite consoles