|

|

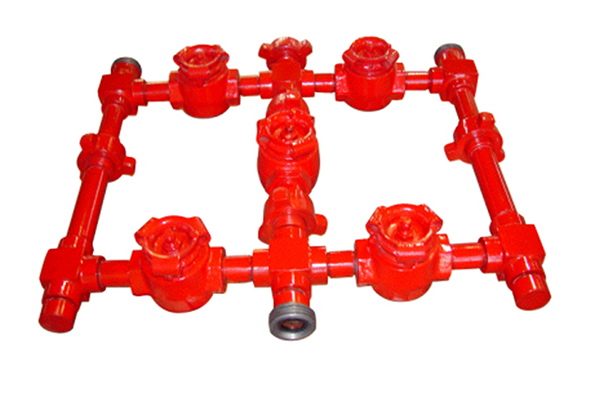

Plug Valve Manifold and Flowline Produces

The plug valve manifold consists of plug valve, choke valve, swivel joint, elbow, tee, corss, union adapter etc.

Design features:

1.New lightweight designs;

2.Integral hammer wing union end connections;

3.Forged construction with full traceability;

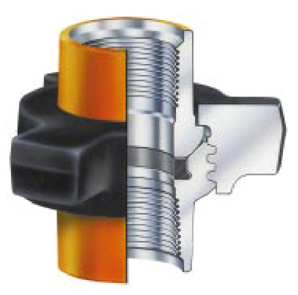

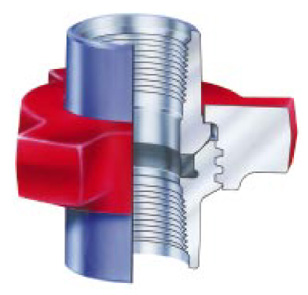

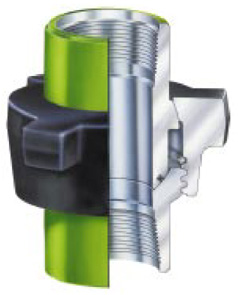

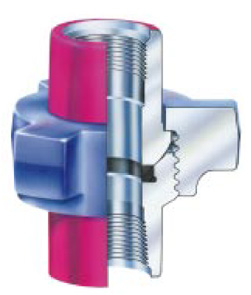

Hammer Union Ends Plug Valve

Hammer Union Ends Plug Valve

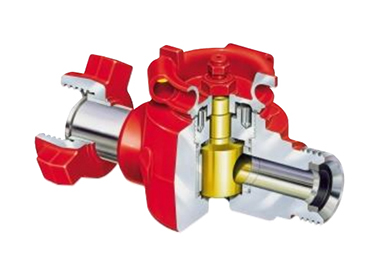

Plug valve is a necessary part that is connected with high-pressure manifold in operation of cementing well and fracture in oil field and also suitable to gighpressure fluid control. As plug valve assembling, the sealing surfaces were coated with high pressure grease made in USAand each valve was hydrostatic tested on strength and seal and no-leakage valve was permitted to provide to user. It features compact structure, convenient maintenance, small torque, rapid open and simple operation, so it is the best valve in cementing/ fracture manifold.

Plug valve mainly consists of valve body, hand wheel, piston and etc.

The outlet adopts union 1502 connection (also ordered as required by user) and column fitting exits between the valve body and liner, the outer circle of which is sealed with seals mounted.

Between liner and piston is sealed with column metal fitting and it features high fitting precision and reliable seal.

Notice: Under the 10000PSI pressure, the valve can be easily opened or closed.

Notice: Under the 10000PSI pressure, the valve can be easily opened or closed.

Operation & Application

Plug valve shall be clean and high-pressure grease shall be injected into valve chamber in time, otherwise there may be leakage on the outlet.

Before usage, it should be inspected whether the opening/closing situation be in line with sign and hand wheel turning at 90 degree can create open/close.

Maintenance

Constant maintenance can prolong the working life of valve;

The clean and injection of oil/grease should be executed after work is over.

Regularly check whether all seals is damaged, the damaged seal should be replaced immediately;

As the seal of the piston and liner fail, it should be disassembled and inspected, it can be polished or replaced.

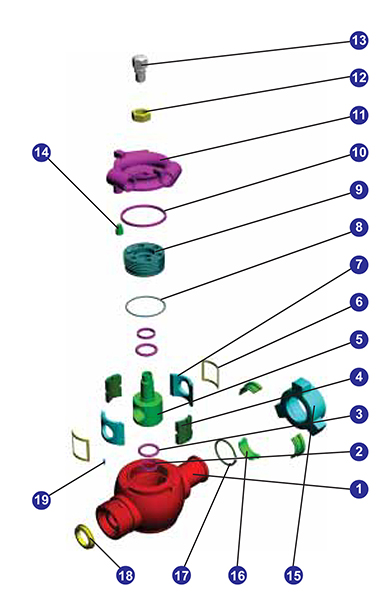

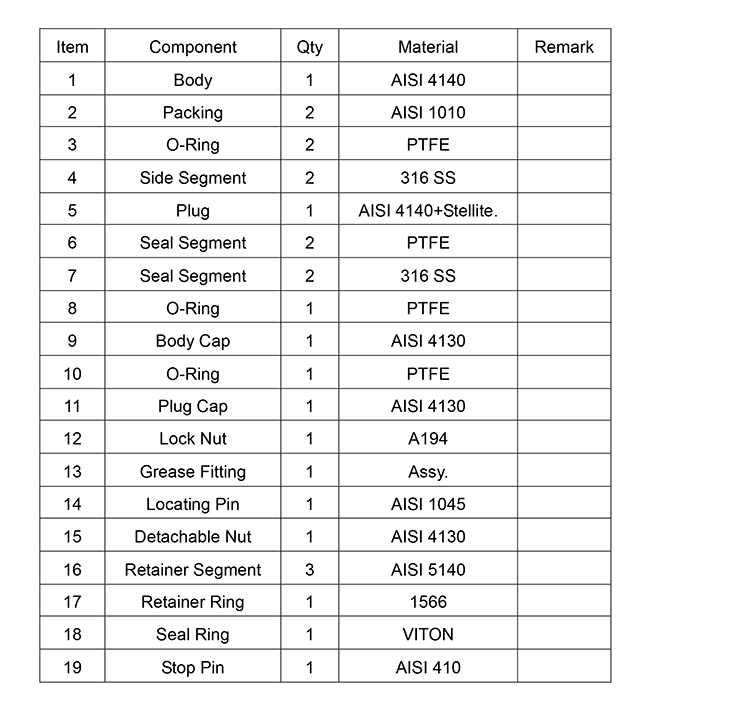

HAMMERUNIONENDS PLUG VALVE PARTS LIST

HAMMERUNION

The Hammer Union can be used for cementing trucks, all kinds of manifolds and other high pressure equipment, and pipes. It is an important part for transporting oil. Water, fracturing fluid and mixed fluid . These products are all made of high quality steel by forging and finishing cut .They have good. mechanical performance and sealing property. Especially they can operate under the bad weather condition. They can be assembled fixed easily and conveniently. Main technical parameter model number collecting norm working pressure ,structural length drift diameter. the product adopts some end connections of pipeline thread, tubing thread, butt-weld.

The Hammer Union type mainly consists of Figure 602, Figure 1002, Figure 1003,Figure 1502 and Figure 2002.

Figure 602 HammerUnion

Nominal pipe Size:1”,2”,3”,4”;

Nominal pipe Size:1”,2”,3”,4”;

Pressure Rating:6000psi cwp;9000 psi test;

Connections Type: pipeline thread, tubing thread, butt-weld;

Component Parts: Nut, Male Sub, Female Sub, Seal Ring;

Sour Service Models to NACE MR-01-75.

Recommended service

Manifold and line connections and mud service.

Features

●Compact;

●Replaceable, lip-type seal provides primary seal, protects secondary metal-to metal seal, and minimizes flow turbulence;

●Butt-weld available;

Figure 1002 HammerUnion

Nominal pipe Size:1”,2”,3”,4”,5”,6”;

Nominal pipe Size:1”,2”,3”,4”,5”,6”;

Pressure Rating:1”to4”10000psi cwp;15000 psi test;5”to6”7500psi cwp;12000 psi test;

Connections Type: pipeline thread, tubing thread, butt-weld;

Component Parts: Nut, Male Sub, Female Sub, Seal Ring;

Sour Service Models to NACE MR-01-75.

Recommended service

Cementing, fracturing, acidizing, testing, and choke and kill lines.

Features

●Replaceable, lip-type seal provides primary seal, protects secondary metal-to metal seal, and minimizes flow turbulence;

●Butt-weld available;

●5”and6”sizes have O-rings for primary seals.

Figure 1003 HammerUnion

Nominal pipe Size:2”,3”,4”,5”;

Nominal pipe Size:2”,3”,4”,5”;

Pressure Rating:2”to3”10000psi cwp;15000 psi test;4”to5”7500psi cwp;12000 psi test;

Connections Type: pipeline thread, tubing thread, butt-weld;

Component Parts: Nut, Male Sub, Female Sub, Seal Ring;

Sour Service Models to NACE MR-01-75.

Recommended service

For high-pressure connections where lines can’t be aligned.

Features

●Ball seat provides positive seal with up to 7-1/2°misalignment;2”model up to 4 ;

●Replacement O-ring on male sub provides primary seal, and protects metal-to-metal seal against abrasion and corrosion;

●Available with threaded or butt-weld ends.

Figure 1502 HammerUnion

Nominal pipe Size:2”,3”,4”;

Nominal pipe Size:2”,3”,4”;

Pressure Rating: 15000psi cwp;22500 psi test;

Connections Type: pipeline thread, tubing thread, butt-weld;

Component Parts: Nut, Male Sub, Female Sub, Seal Ring;

Sour Service Models to NACE MR-01-75.

Recommended service

Cementing, fracturing, acidizing, testing, and choke and kill lines.

Features

●Replaceable, lip-type seal provides primary seal, protects secondary metal-to metal seal, and minimizes flow turbulence;

●Butt-weld available;